SOCOTEC is a leading provider of asbestos management and consultancy services across a wide range of business sectors and property types.

Below the Surface: Locating Hidden Asbestos During ‘Intrusive’ Surveys

It is a legal requirement under the Control of Asbestos Regulations (CAR) 2012 to prevent the uncontrolled disturbance of asbestos-containing materials (ACMs) prior to any major refurbishment or demolition work taking place on any given structure that was built/refurbished before the year 2000. In order for all ACMs on the premises to be located and identified as far as is reasonably practicable, refurbishment or demolition surveys are required, with intrusive techniques implemented in order to determine whether asbestos is located in hidden and/or inaccessible locations.

In these FAQs, James Dodgson, commercial director, Asbestos, SOCOTEC UK, explores the challenges posed when duty holders place limitations on the scope of intrusive work conducted during refurbishment or demolition surveys, as well as the impact that this can have on surveyors in the event of any ‘unknown’ or ‘missed’ materials being discovered further down the line.

Intrusive Surveys FAQs

During refurbishment or demolition surveys, surveyors will gain access to all of the areas where the works are planned to take place, checking for any asbestos that may be hidden from the naked eye and/or is difficult to reach. In order to access areas that are difficult to gain entry to, surveyors are required to carry out the necessary level of damage using specialist equipment to determine which materials the building has been constructed with and whether or not they contain asbestos. In order to do this, the survey areas must be unoccupied, with the surveyed areas being proven as fit for reoccupation upon completion and before inhabitants are allowed entry.

Aggressive inspection techniques enable surveyors to access hard to reach structural areas between walls, floors and underground services, and can include the lifting up of carpets and tiles, breaking through walls, ceilings, cladding and partitions and opening up floors. When carrying out these intrusive works, appropriate control measures should be put in place to ensure that the level of damage does not make the building structurally unsound, while also preventing the spread of debris. This is why it is so important to ensure that the areas are completely unoccupied prior to these surveys taking place.

As a general rule of thumb, there should be no restrictions on the level of access permitted during a refurbishment or demolition survey unless the site in question is ruled unsafe or if access is physically impractical. However, prior to these surveys taking place, both the surveyor and the duty holder will need to discuss access arrangements and the extent of the damage required as part of the planning stage of the contract. Where access is not possible, surveyors must clearly locate these areas on plans and within the survey report itself to ensure that all parties are fully aware of any areas of concern and whether further action is required.

Despite intrusive surveys only causing damage to the areas where the proposed refurbishment or demolition is due to take place, duty holders often request that surveyors locate and identify all hidden ACMs without causing any significant damage to the building. By placing restrictions on the scope of the intrusive works required, the surveyor is unable to accurately locate and identify all ACMs on the premises that fall within the remit of the survey, increasing the risk of hazardous materials remaining undetected. This has the potential to impact the accuracy of the refurbishment or demolition project that the survey has been commissioned for, particularly if ACMs are identified and require subsequent removal further down the line (with a 14-day notification issued to the HSE beforehand). In addition, there is a risk to the workforce unknowingly disturbing and exposing themselves and others around them to the concealed ACM.

The extent of intrusion required within a refurbishment or demolition survey will vary from premise to premise, with factors that affect the extent of the intrusion required including the type of building, its accessibility and the nature of the construction work being carried out. Surveyors will relay the scope of the investigative work required to the duty holder, who will then state whether or not they are happy for this level of intrusion to take place. Any restrictions on the survey should be discussed between the duty holder and surveyor prior to the commencement of the works, with evidence of this agreement clearly documented. In situations where an area is being reoccupied following the survey and prior to the project works, building custodians can be rightly nervous about decorative damage and the unsightly condition that can follow an intrusive survey. In these cases, it may be that an attendance from third parties is required to ‘reinstate’ the building condition.

If any area cannot be accessed by the surveyor for any reason once the survey is underway, it is imperative that the duty holder is informed as soon as possible, with arrangements made for additional access where required. However, if further access is physically impossible, the survey report should flag up these areas to ensure that there is a full understanding of remaining ‘risk areas’. With this information, the duty holder must then ensure that they have the appropriate management and emergency procedures in place to safely deal with any suspicious or unknown materials if they are uncovered.

How can SOCOTEC help?

SOCOTEC’s highly experienced team of asbestos consultants are fully accredited to carry out asbestos management, refurbishment or demolition surveys to UKAS No. 0148 standards. If you would like to receive further information on how SOCOTEC’s Asbestos team can help your business to comply with its Duty to Manage, click here or get in touch.

Want to find out more about Asbestos Surveys? Contact us

Click hereAsbestos Training FAQs

Asbestos training requirements are specific to the roles and responsibilities of individual employees, therefore a training needs analysis should be undertaken to determine specific requirements for each role within your business.

Regulation 10 of the Control of Asbestos Regulations 2012 governs asbestos information, instruction and training requirements, meaning that employers have a legal duty to ensure their employees are suitably trained.

There are three levels of asbestos training:

Asbestos awareness

Non-licenseable work with asbestos including NNLW

Licenseable work with asbestos

Levels 2 and 3 are for individuals who will be deliberately working on, or disturbing, asbestos containing materials, while level 3 is limited to Licensed Asbestos Removal Operatives. Asbestos awareness training is designed to avoid accidental disturbance of asbestos materials and is required to be provided to any employee who could conceivably disturb asbestos containing materials during their normal work activities and also those individuals that manage and control the same activities. This includes trades such as carpenters, plumbers and electricians but also those controlling and influencing works, such as architects, project managers and building consultants.

Training should be refreshed regularly to ensure ongoing awareness and the refresher can take many forms including e-learning or in-house delivery via a competent individual.

There is no legal requirement for awareness training to be an accredited course, however, the trainer should be experienced and competent in the subject and the course content should meet the legislative guidance.

There are a number of organisations whose members provide asbestos training courses.

The COVID-19 pandemic continues to impact every aspect of our lives, including the ways in which we enhance our Continuing Professional Development (CPD). One significant impact that COVID-19 has had on learning and development is the number of people signing up to undertake or refresh their Asbestos Awareness training, with course uptake experiencing considerably lower numbers than usual.

While the risk posed by degradation of asbestos-containing materials may have increased due to less maintenance being undertaken in buildings over the course of the national and regional lockdowns, the risk of actual human exposure may have subsequently decreased as a result of lower occupancy. Therefore, once these properties begin to return to normal levels of occupancy the risk of exposure potentially increases.

With this in mind, it is more vital than ever for those whose line of work means they may come into contact with asbestos materials to competently identify and manage the level of associated risk, all while remaining up-to-date with health and safety guidance and current legislation.

Since the reopening of construction sites in May 2020 after the first national lockdown, the number of workers undertaking Asbestos Awareness training has remained well below average and is currently at its lowest rate in five years. This rate has also been impacted by those operating in other sectors that require Asbestos Awareness training who have now switched to working from home on a permanent basis. To put this into perspective, an average of 18,000 workers per month completed asbestos training pre-pandemic, whereas from March to August 2020, an average of only 6,000 workers per month undertook the training (a decrease of more than 66%). For this reason, UKATA is calling for providers across the UK to stress the importance of keeping up-to-date with Asbestos Awareness training to employees.

The HSE recommends that some form of refresher course is undertaken to ensure that up-to-date knowledge of asbestos awareness is maintained. This is usually every 12 months, but frequency could depend on the level of potential exposure. However, many organisations are continuing to make up for time lost over the initial lockdown, and have therefore taken their eyes off the ball when it comes to ensuring that their staff have up-to-date Asbestos Awareness training.

Regulation 10 of The Control of Asbestos Regulations 2012 requires every employer to ensure that adequate information, instruction and training is given to their employees who are or who are liable to be exposed to asbestos, or who supervise such employees. This is not only to remain compliant with health and safety legislation and their duty of care, but also to protect the lives of employees and the general public. By regularly undertaking Asbestos Awareness training, delegates will be equipped with the information required to help them to recognise the properties of asbestos, where it is/has been used in buildings, when it may pose a risk to health and how to respond accordingly in the event of exposure or disturbance.

How can SOCOTEC help?

SOCOTEC’s Asbestos team can deliver face-to-face Asbestos Awareness courses in line with social distancing guidelines, as well as offering virtual classrooms via Microsoft Teams that can be tailored to your business’ individual requirements. Available via the online Shop, SOCOTEC offers the UKATA Asbestos Awareness e-learning course and refresher training to ensure that professionals are fully equipped to identify and manage asbestos exposure. In response to client feedback, the content within the Asbestos Awareness online course has recently been updated, with additional factual and visual information implemented to improve the user’s overall learning experience.

Any delegates that purchase the UKATA Asbestos Awareness e-learning course before the end of January 2021 can take advantage of a £10 discount, with the training available for £15. Please note that UKATA Asbestos Awareness course and refresher training is also available as a half-day classroom-based course – click here to find out more.

For further information on SOCOTEC’s range of training courses, click here or get in touch with a member of our Health & Safety Consultancy. Alternatively, if you would like to find out how SOCOTEC can support your business with its asbestos management requirements, click here.

Asbestos Discoveries FAQs

When it comes to asbestos, roofing and insulation materials tend to be the first things that come to mind. However, not everyone is so aware of the other common materials that may contain asbestos; the HSE list a few examples, such as sprayed coatings, flooring, and textured coatings – all of which pose a health risk if disturbed without suitable precautions.

Many buildings that were constructed before 2000 are highly likely to contain asbestos with more than 500,000 public buildings still containing asbestos today. Due to its tensile strength and properties as a thermal and electrical insulator with good chemical resistance, asbestos was widely used in construction materials – right up until its ban in 1999.

Some asbestos containing materials are higher risk than others, depending on the likelihood of asbestos fibres being released into the atmosphere.

Asbestos cement products, for example, are only likely to release fibres if the product is broken or damaged – the content of asbestos is also relatively low at around 10-15%. During original production, the asbestos was mixed into cement products to increase their strength. Once set, the fibres were contained within the cement matrix. Only when broken, damaged or planned construction/remediation works are taking place would asbestos exposure need to be considered. Asbestos cement water tanks are just one example of where asbestos cement products may be hidden in an industrial building; cladding, roofing, gutters and pipes are other typical applications.

Lagging, on the other hand, can contain up to 85% of asbestos. Used as thermal insulation around pipes and boilers, asbestos was an obvious choice to prevent heat escaping, as well as for fire prevention methods. Substitutes have been used since the ban, but asbestos-based lagging is still found in many buildings. Disturbance of lagging is fairly easy, even though it is often covered in a protective coating. Because of this, and due to the high asbestos content, asbestos lagging is classified as a high risk material and should only be handled by licensed asbestos contractors.

The list above is not exhaustive. Even after the ban on asbestos use in November 1999, there have been cases of stockpiled ACMs being used through the construction supply chain.

Increasingly, the widespread reality of asbestos risk is hitting headlines and often in the most unexpected of places. Over the past 12 months, The Independent and BBC have reported on asbestos fibres found in makeup items, mesh gauzes, talcum powder and crayons.

An article written by The Independent declares the asbestos-contaminated makeup originated from China, but did not contain a list of ingredients on the packaging. Only when tested by a consumer did the presence of asbestos become apparent and action was taken to remove the contaminated item from the shelf. Similarly, a public interest group discovered the presence of asbestos in crayons. Each are troubling incidents that places the risk of asbestos at the forefront as, despite its ban in the UK in 1999, asbestos is still very much present throughout the country. Asbestos has even been found in cigarettes where unscrupulous black market cigarette manufactures use it as an additive with examples being identified in Ireland and in the UK.

Just last year, 19 years after the ban, schools were alerted to the potential risk that recently supplied gauze mats used in science blocks may contain asbestos. This incident came as a result of a number of companies unknowingly importing asbestos containing products leading to the HSE providing advice that ‘Any gauze that contains asbestos should not be used, and it must be safely disposed of as asbestos waste.’

Even with asbestos banned in 66 countries around the world, the asbestos economy continues to grow in China – one of the world’s largest producers of asbestos – as well as Russia, Brazil and Kazakhstan. In 2017, an estimated 900,000 metric tonnes of asbestos were produced in Russia and China alone. Which raises the question: is asbestos still a threat to the UK supply chain?

New products appearing in the marketplace is quite a different concern to the legacy items of asbestos in building materials. Since the ban in 1999, there is the assumption that new products will not pose a risk. For legacy items and pre-2000 buildings, suitably trained persons will be aware of the presence of asbestos in items such as insulation boards, construction materials, lagging and fire proofing – knowing where to exercise caution. For items such as make-up, toys and crayons, the risks are unexpected.

Asbestos-free declarations can be made for products imported from overseas but this relies on transparency and accuracy of the supply chain.

Imports into the UK should be declared 100% free from asbestos, covering the complete product including any fittings, equipment, cables, gaskets, glands, packing, brake linings, lagging insulation. Yet even this causes controversy as asbestos-free declarations can vary, depending on the country. Asbestos content in the EU can be 0.1% and still be considered asbestos-free, whereas the USA defines asbestos-free as containing up to 1% of asbestos content. Worse still is that some Asian countries consider ‘asbestos free’ to mean less than 10% asbestos content.

Since 2005, the World Health Organization has urged its members to work toward eliminating mesothelioma and other cancers caused by avoidable exposures to carcinogens at work and in the environment. As asbestos is impossible to identify with the eye, ensuring asbestos remains outside of the UK must be met with due diligence and quality control checks at all areas of the supply chain. Testing for asbestos to determine if asbestos is present is one way in which an asbestos laboratory can support vigilance and ensuring the supply chain is trustworthy in bringing asbestos-free products into the UK marketplace.

When the Asbestos Prohibition (Amendment) Regulations 1999 banned the import, supply and use of asbestos and asbestos-containing materials (ACMs) in the UK, HSE guidelines stated that no asbestos fibrous minerals should be contained within commercial and non-domestic buildings constructed after the year 2000. But what is the recommended course of action when asbestos is discovered within post-2000 buildings?

Legislative loopholes

According to recent research, of the six million tonnes of asbestos imported into the UK, a substantial amount still remains in an estimated 1.5 million commercial buildings, as well as in over 2m private domestic properties.[1] [2] While the majority of these will be buildings constructed prior to the 1999 ban, there have been many occasions where asbestos will have been physically transported onto post-2000 premises unbeknownst to the inhabitants.

Despite the legislation prohibiting the supply and usage of ACMs, there was in fact a loophole which excluded materials that were already in use prior to the ban being enforced. As a result, existing stocks of materials and products containing the fibrous mineral were permitted to remain active until they reached the end of their service life, and exemptions on the use of chrysotile were still in place until as late as 2005.[3] As the ban did not legally mandate the removal and eradication of asbestos-containing products, it is easy to presume that such materials that were well within their service life could easily have been transported into properties constructed after the year 2000.

There have also been cases where stockpiled ACMs have been used throughout the construction supply chain, particularly when taking importation legislation into account. British law states that all imports coming into the UK should be declared 100% free from asbestos; however, the declaration level outside of the UK varies considerably. Across Europe, the asbestos-free level is 0.1%, the USA at 1% and less than 10% across parts of Asia, meaning that there is room for error for ACMs to be imported in the UK.[4]

Another example of asbestos discovery within buildings constructed after the 1999 ban is on brownfield sites, particularly when pre-2000 commercial and industrial buildings are demolished or redeveloped to make way for new premises. Asbestos is frequently discovered within the soil, rubble and debris of brownfield sites for a number of reasons, such as the site having been used for fly tipping, or if the redeveloped site was demolished prior to the implementation of the asbestos ban. It can also occur when those responsible for the redevelopment works do not take the required time and care to properly dispose of construction materials, or when they use asbestos-contaminated soil as top soil or backfill.

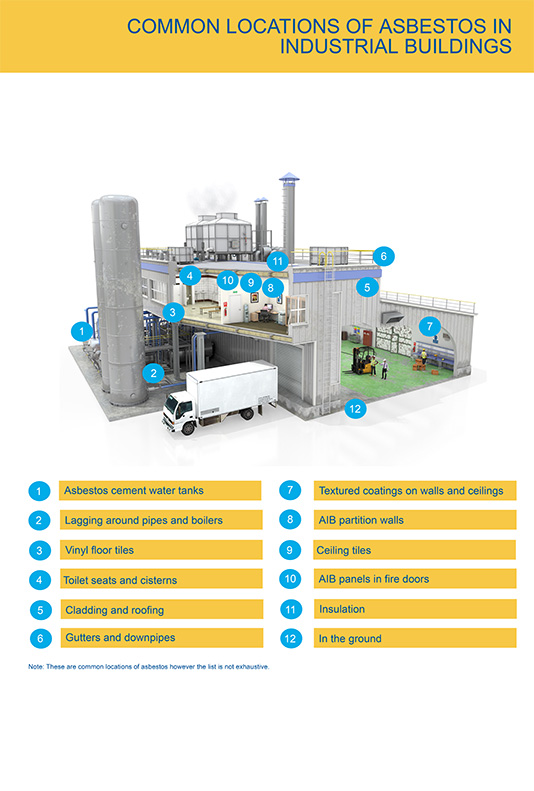

Where can asbestos be found?

Renowned for its insulating, heat resistant and strengthening properties, asbestos was commonly used within a range of different construction materials in the late 20th century, including roofing, sprayed and textured coatings, insulation materials, ceiling and wall panels, cladding, floor and roof tiles, textiles, soffits, water tanks, pipe lagging and gutters. Its versatility meant that it could be found in a range of locations within a building, from airing cupboards and fuse boxes to fireplaces and boilers.

Asbestos insulation board and cement also featured heavily in common household objects in the late 20th century, having been incorporated into such products as hairdryers, safes, dishwashers, ovens, washing machines, toasters and ironing boards. The fibrous mineral has also been discovered in more unusual objects over the years, including make-up, toilet seats, jewellery, cameras, radios, crayons, books, toys and even talcum powder. Collectors of antiques are required to proceed with caution when bringing these goods onto the premises, as this is yet another way in which asbestos can be discovered within a post-2000 property.

Post-2000 discoveries – examples from SOCOTEC’s Asbestos team

Over the years, members of SOCOTEC’s Asbestos team have uncovered the fibrous mineral on a wide range of premises constructed after the nationwide ban. As aforementioned, it is extremely common for older plant and equipment to be transferred into ‘newer’ buildings, either due to the fact that it is asbestos-containing or it has been brought in from a site surrounded by the hazardous fibres. This was the case in a UK prison surveyed in the early 2000s, which was found to be asbestos-containing following the discovery of plant that had been transferred from an older building containing asbestos gaskets.

Similarly, an old factory site full of asbestos was closed and relocated to a brand new, purpose-built facility constructed in 2004. As this was built after the ban, it was presumed that no ACMs were used within the construction materials, with no asbestos reinspection required. However, a group of old industrial ovens were transferred from the older site and into the new factory, all of which were asbestos-containing.

As aforementioned, stockpiled construction materials have often been the cause of newer buildings being contaminated with asbestos fibres. Due to the fact that the 1999 legislation allowed asbestos-containing materials to be used until the end of their service life, it was common practice for builders to hold onto these or salvaging them from damaged or demolished structures to be used again. This was the case during an asbestos survey of a school in 2002, where a surveyor noticed that the contractor was re-roofing the veranda using asbestos-containing tiles.

Recommended actions

The general rule of thumb for duty holders or owners of buildings constructed after the year 2000 is to presume that there will be no asbestos located on the premises. However, it is still good practice to remain vigilant about the possibility of the fibrous mineral being present, such as within old electrical equipment that has been transported into the building, or if post-2000 premises are built on existing basements or linked to adjoining structures.

Legislation and HSE guidance currently recommends that an asbestos-containing material can be left if it is in good condition and unlikely to be disturbed or damaged, as it is only harmful to health when fibres are released into the atmosphere. However, if a material is presenting signs of ageing, damage and/or deterioration, or if repairs or refurbishment are to take place on or near to the material, it is recommended that you call in a suitably trained individual to survey the level of risk and recommend remedial action.

If you suspect that your post-2000 property may contain asbestos, SOCOTEC’s asbestos management and consultancy services can support you to remain compliant with the ‘duty to manage’ requirement of the Control of Asbestos Regulations 2016. SOCOTEC also offers UKATA-accredited Asbestos Awareness training* both through face to face course and an online e-learning platform, which provides delegates with the knowledge required to effectively manage and control the risks associated with asbestos exposure.

References

1 https://www.asbestos.com/news/2019/11/27/report-million-uk-buildings-contain-asbestos-infographic/

2 https://www.fia-online.co.uk/wp-content/uploads/2017/10/Asbestos-HSE.pdf

3 https://www.ukpandi.com/fileadmin/uploads/uk-pi/legal/Lowe.pdf

4 https://www.socotec.co.uk/news/faqs/faqs-asbestos/

asbestos in an industrial setting

Locations of Asbestos

Download the diagram gives an overview and provides examples of where asbestos may have been used in an industrial setting.

Download the diagram gives an overview and provides examples of where asbestos may have been used in an industrial setting.

Asbestos Removal FAQs

The short answer is no, asbestos containing materials do not have to be removed when they are located or as part of a phased removal programme thereafter. In fact, it is often more dangerous to remove the materials than it is to manage them in situ. The HSE guidance states that asbestos containing materials (ACMs) in good condition that are unlikely to be disturbed, should be managed and not removed.

If ACMs are in bad condition or likely to be disturbed by normal occupation or indeed by project work, you may need to consider remedial actions. One such option would be to remove the materials but it may also be feasible to repair, ‘encapsulate’ or protect the materials to prevent damage and reduce risks.

In addition, you may wish to consider redesigning project activities to work around any ACMs, making contractors aware of the location and mitigating the risk of disturbance by avoiding direct contact.

Where all other options are not suitable or the material is in very poor condition, your only option may be to remove the ACM entirely. Where licensable materials (such as lagging, sprayed coating or insulating board) are concerned you will most likely need to engage a licensed asbestos removal contractor to undertake the work, and they will need to submit a notification to the enforcing authority. Where a notification for licensed work is required there is a mandatory ‘standstill’ period of 14 days before the work can commence.

For lower risk materials (such as floor tiles and cement sheeting), you can use a non-licensed contractor to remove the materials, however you must still ensure the contractor is competent to undertake the work (has suitable risk assessments and method statement) and that they dispose of the resulting waste correctly. They may also need to submit a notification to the enforcing authority if significant deterioration of the material will take place during removal, but in these instances work can commence immediately following issue of the notification.

If you’re developing land that is contaminated, you may be eligible to make a tax relief claim assuming that the conditions below (in addition to other criteria) apply:

The contamination is as a result of industrial activity including construction, gas generation, mining or manufacturing

The contamination has not been caused or planted by the claiming party

The land is out of use and must be remediated before reuse is possible

You are a company conducting land remediation expenditure

Land Remediation Relief (LRR) was introduced in 2001 (and revisited in 2009) to encourage the redevelopment of disused and contaminated sites, by offering a 150% tax deduction.

Gov.uk states that companies can elect to treat qualifying capital expenditure as a deduction in computing taxable profits - whereby remediation has been required to remove or contain contamination so relevant harm is no longer an issue. LRR provides a deduction of 100% of the qualifying expenditure, plus an additional deduction of 50%.

Asbestos contamination within the ground has become increasingly challenging for anyone seeking to develop brownfield sites. Additionally, asbestos in building materials may also need to be remediated as part of the development, with the cost of which classified as ‘qualifying expenditure’. While the name suggests the relief is available for contaminated land, it also can apply to buildings.

Where guidance is being sought to aid in the remediation of such contaminated sites, LRR can be claimed to support the qualifying remediation expenditure. The relief available varies depending on whether you are the owner/investor or the developer.

As an asbestos and contaminated land consultancy provider, and not an accountancy specialist, SOCOTEC is not able to directly advise on financial claims in relation to LRR or other tax related matters. For financial advice, please contact an accountancy firm who should be able to offer a range of financial advice and services. SOCOTEC can, however, provide a number of asbestos and contaminated land consultancy services in relation to asbestos in soil, ground and construction material contamination – click here to find out more or contact us.

Compliance

There is no legal requirement for a company to have a dedicated asbestos manager, however many large companies do have such a role within their business. All non-domestic premises will have at least one asbestos ‘Duty Holder’ who is responsible for complying with the asbestos regulations in relation to that property. For large organisations this role is likely to be shared across a small number of individuals but the company’s asbestos management plan will define how the role is discharged and what each person’s role is.

All companies who own, or manage, properties where they have a responsibility for maintenance and access to/from the property must have an asbestos management plan and take measures to ensure they comply with the Control of Asbestos Regulations 2012.

Appointing an ‘Asbestos Manager’ or ‘Corporate Duty Holder’ within an organisation can help provide focus to the various tasks that must be undertaken to ensure asbestos compliance is maintained. Tasks such as, coordinating the regular re-inspection of asbestos materials, managing the delivery of training courses across the business, updating policy and procedures, liaison with asbestos consultants and removal organisations, and auditing internal and external processes.

Where a formal dedicated role is not warranted, perhaps due to the relative size and complexity of a company’s buildings, it is important that the individuals who hold responsibility for discharging the various duties associated with asbestos management are suitably competent in doing so and are fully aware of their responsibilities.

‘Asbestos: The Analysts’ Guide for sampling, analysis and clearance procedures’ contains guidance for analysts involved in asbestos work and is the authoritative source of asbestos analytical procedures. The guidance is also designed to help analysts and their clients comply with the Control of Asbestos Regulations 2012 and the associated Approved Code of Practice (ACoP) and guidance L143 (Second Edition)2.

It is expected that the revised version of the analysts’ guide will specify additional client involvement in the asbestos removal process. Our experts have outlined the main expected changes for clients below:

Engaging asbestos analysts for four-stage clearance and other work

Clients can engage analysts for a whole range of asbestos sampling and analysis activities and to provide advice and consultancy services. Note that analysts need to be accredited by UKAS for most asbestos related work. Details of analysts can be found on the UKAS website. Clients should check analyst references and examples of previous work to ensure competency.

Asbestos removal

It is recommended that clients engage analysts directly rather than through an asbestos licensed contractor

It is advisable that the analyst discusses with the client the expected level of cleanliness for the removal work

There will be some impact on the time, and therefore cost, of carrying out four-stage clearances due to:

Increased time on site by the analyst. The client needs to be aware how long the thorough visual inspection part of the 4-stage clearance will take (should be discussed with analyst). The time will be inserted in the front page of the completion document for the work. This is the “Certificate for Reoccupation” (CfR)

The necessity for the analyst to make a comprehensive photographic record of the work

Once the work has been completed the client should:

Check the report thoroughly including ensuring photographs show clearly that areas are visually clean

Check the CfR time taken for the thorough visual inspection against the estimated time. Where there is a large difference (eg 20% or more), seek an explanation

If issues are raised during the work then the client should discuss these with the analyst

Dust sampling – advice is given on sampling and potential difficulties of interpreting the results. Dust sampling is not recommended as a standard practice and the guidance suggests it is only used in circumstances such as assessing the spread of an asbestos containing material (ACM) from poorly controlled maintenance, removal work or recent incident

Asbestos in soil – guidance on sampling and procedure for identification are now included in the guidance for completeness

Keep updated

As the UK’s leading provider of testing, inspection and compliance services, we aim to keep our clients up-to-date with the latest industry news and changes to legislation. Although there is not yet a date for the release of the revised asbestos analysts’ guide, we will continue to keep you posted. Look out for further information in the coming weeks.

SOCOTEC has UKAS accreditation No.0148 for asbestos surveying and No.1089 for asbestos testing.

When it comes to managing asbestos, it often goes beyond the legal responsibility to simply identify asbestos containing materials (ACMs), assess the risks and manage those risks.

Having a specialist asbestos consultancy on board to offer independent advice and a wider perspective can support your organisation in many ways. The development of a collaborative relationship where a core understanding of the specific constraints, concerns and requirements can lead to added value and the development of strategies offering genuine return on investment.

When looking at the management of asbestos in the short term, mid-term and long term, both the health and safety and cost implications should be reviewed; it should never be a case of “Let’s just get this asbestos out”. Often, it can be more dangerous to remove the asbestos containing materials than it is to manage them in situ. If the ACM’s are in good condition and unlikely to be disturbed or damaged, then they could be managed and not removed.

This is both a cost and time-saving benefit, without compromising on safety. By not rushing in and removing all identified asbestos immediately, a management approach can be established based on a full and developed understanding of asbestos risk across the building, site or property portfolio. Where budget constraints are in place, a risk based approach to asbestos management can help to identify priorities:

Refined risk categorisation

Low risk removals that can reduce annual re-inspection costs

Other management approaches offering better value for money when compared to simply removing.

Using an independent asbestos consultancy means you will have peace of mind that the advice given is the best option for you, as the client, with cost savings recommendations given where appropriate.

On a regular basis, as an independent consultant, part of our role is to review recommendations for asbestos removal. Often clients are removing their asbestos because they’ve been advised to do so, but it is fundamental that the advice given is by a competent consultancy, following the completion of a survey to ensure the asbestos has been fully risk assessed.

Asbestos removals, unless in an emergency, should be completed following a complete review of the asbestos risk, a fully UKAS accredited asbestos survey and discussion with all stakeholders. For situations where asbestos removal is required, there is a legal requirement for an independent asbestos analyst to be appointed to complete the four stage clearance procedure. Early stage involvement in the development of the removals strategy and/or specification provides a greater and more developed understanding of the overall requirements; when it comes to ratifying that all works have been completed as required, early stage involvement has proved to be invaluable.

The 24 November 2019 will mark 20 years since the UK outlawed the import, manufacture, supply and use of asbestos containing materials (ACMs). The Asbestos Prohibition (Amendment) Regulations 1999 formed the pinnacle of a series of laws that were put into place from the early 1970s, as the debilitating health risks associated with the inhalation of asbestos fibres became increasingly apparent and pressure for a national ban began to mount.

Asbestos production and usage was at its peak in the 1960s and 70s, with over 170,000 metric tonnes produced per annum and more than 3,000 ACMs on the market.[1] Despite voluntary bans on blue (crocidolite) and brown (amosite) asbestos in 1970 and 1980, it wasn’t until 1985 that the first of the Asbestos Prohibition Regulations completely prohibited the trade and use of these materials, as well as the production of new ACMs. As white asbestos (chrysotile) was considered the least dangerous, this continued to be imported, supplied and used until the national ban was enforced in 1999. However, it should be noted that exemptions for certain materials containing chrysotile were permitted until as late as 2005, with current legislation still enabling the Ministry of Defence to use ACMs if it is in the interests of national security.

Since the Asbestos Prohibition Regulations were passed, new legislation was introduced in 2002 and updated in 2006 and 2012 to further improve health and safety. Procedures are now in place to identify, manage and safely remove asbestos, and there is also a requirement for written records and constant medical surveillance for workers frequently exposed to the fibrous minerals. Nevertheless, as we approach the 20th anniversary of the national ban, asbestos continues to pose a considerable risk to UK citizens.

While it would be easy to presume that the rest of the world has recognised the health risks posed by asbestos and acted accordingly, this is certainly not the case. Russia, India and Kazakhstan are responsible for 90% of global asbestos production, with research from the US Geological Survey indicating that usage within these areas remains at a steady or slightly increasing rate.[2] For instance, in Kazakhstan, the production of asbestos increased from 192,000 metric tonnes in 2016 to 200,000 metric tonnes in 2017, while production in China remained at a consistent rate of 200,000 metric tonnes from 2016-17.

Responsible for exporting 60% of the overall global asbestos volume (over 400,000 tonnes respectively) and generating 0.69m metric tonnes in 2018 alone, Russia continues to mine, produce, use and trade asbestos at an increasing pace.[3] Despite the passing of a revolutionary law on 7 September 2011, which promised – yet failed to enforce – protective measures that would significantly reduce exposure, the nation continues to demonstrate a lack of transparency on the risks and hazards posed by asbestos, with millions relying on the fibrous mineral to insulate their homes.

As one of Russia’s key importers, India continues to trade and use large quantities of asbestos, despite the Indian government banning both asbestos mining and asbestos waste. While the Indian Factory Act and Bureau of Indian Standard have regulations in place regarding the safe usage of ACMs, these have never been properly enforced, which means that such products continue to be used freely without any regard for health and safety. As a result, the fibrous mineral continues to be used across roofing, brake lining and insulation material, with the majority of buildings and automobiles across India still containing ACMs.

Currently, there are 66 countries that have enforced a national ban on the use of asbestos. However, it should be noted that several of these countries have passed legislation where certain exemptions can be made. For instance, while a ban has legally been enforced in the Seychelles, the country continues to import and use ACMs, while New Zealand allows ACMs to be imported if there is no asbestos-free alternative available, the cost for an asbestos-free product would be considerably higher, or if the ACM was being used for research and development purposes. A full list of the countries where all types of asbestos are prohibited can be found here.[4]

The Canadian government also recently passed a ban on asbestos, which came into effect on December 30 2018. However, there are a number of exemptions within this piece of legislation which still allow the use of asbestos within the military, nuclear facilities and for magnesium extraction from asbestos mining residue. This has been met with considerable protest, as many believe that the ban contains too many loopholes and is therefore not strong enough to enforce proper precautionary measures.

Colombia has most recently implemented an asbestos ban, with legislation prohibiting the mining, usage, production, commercialisation and exportation of the fibrous minerals passed on June 12 2019. This comes as a major victory for the Colombian government, which suffered seven consecutive defeats to its proposition to enforce an asbestos ban for the last 12 years. The new law will come into effect in 2021 and will include a five year transition period for companies that currently use asbestos to make the switch to a safer alternative.

20 years later, asbestos continues to remain an ongoing health concern in the UK, with 5,000 people dying of asbestos-related diseases such as Mesothelioma each year – double the number of fatalities caused by road accidents. In fact, Cancer Research UK revealed that the UK has the highest amount of asbestos-related mortalities in the world, which have increased by 887% since the 1970s.[5] As the ban only went so far as to prohibit the production and usage of new products and materials containing asbestos, there still remains no legislation in place that requires the removal of all existing asbestos from all premises. Consequently, a high number of properties still contain forms of ACMs that are hidden or unidentified, which explains why asbestos-related diseases remain a key cause for concern for the UK government.

Private domestic properties remain exempt from the Control of Asbestos Regulations 2012, placing hundreds of thousands of UK homeowners at continual risk of exposure and asbestos-related disease. This is because the law only enforces a duty to manage on those overseeing non-domestic premises, contributing to the estimated 14m private domestic properties that were built when asbestos was still being used as a construction material and, therefore, are at risk of exposure.[6] It should also be noted that the UK ban has not legalised the eradication of asbestos containing products, and to this day the government has failed to implement any measures encouraging its removal (The Netherlands, Australia and Poland have since put regulations in place to enforce this).

1.5m UK commercial premises constructed before 2000 are still suspected to contain various forms of asbestos. This is because the ban does not include the prohibition of ACMs that were already in use prior to the law being passed, meaning such materials and products can remain active until the end of their service life. This left around 6m tonnes of asbestos within UK buildings constructed before the late 20th century, particularly in schools and hospitals.[7] According to the Asbestos in Schools Group, 85% of UK schools have been revealed to contain asbestos, despite the rising demand for all premises to be surveyed and all ACMs to be regularly inspected/monitored.[8] When this percentage is considered alongside the thousands of factories, offices, hospitals and other workplaces across the UK where asbestos is unknowingly present, it is easy to see why asbestos-related diseases remain prevalent to this day.

Safety and compliance

Asbestos continues to pose as a major health threat to UK citizens, with further action required in order to fully combat the risk and ensure that all premises and facilities are compliant and safe. However, certain measures have been put in place since the ban in an attempt to slowly but surely dissipate the problem.

Training is now obligatory for any individual liable to asbestos exposure in the workplace, with effective control measures also in place for both licensed and non-licensed contractors to carry out inspection and removal work. Moreover, if a property is suspected to contain asbestos, a survey is required to determine the location, type and condition of the mineral, and the level of risk assessed, managed and safely controlled. UK legislation currently recommends that if existing ACMs are in good condition and are not likely to degrade/become damaged, they may be left in place. Asbestos fibres are only dangerous if they are moved or disturbed, so their condition needs to be regularly monitored and managed to ensure they do not become airborne and, therefore, potentially inhaled.

If you are unsure as to whether or not your property may contain asbestos, SOCOTEC provides a consultancy service to support you in becoming fully compliant and ensuring the safety of individuals who work within the premises. There is also the option of undertaking training, which will equip workers with the knowledge and skillset to safely and correctly manage asbestos, as well as any asbestos-related emergency.

References

1 http://asbestosvictimadvice.com/2016/01/asbestosis-and-mesothelioma-a-ghostly-trail-of-suffering-into-2016/

2 https://pubs.usgs.gov/circ/2006/1298/c1298.pdf

3 http://anroev.org/aban/wp-content/uploads/2011/12/A-BAN2011_Olga.pdf

4 http://www.ibasecretariat.org/alpha_ban_list.php

5 https://www.cancerresearchuk.org/health-professional/cancer-statistics/statistics-by-cancer-type/mesothelioma/mortality

6 https://www.dedicatedaccidentsolicitors.co.uk/blog/where-is-asbestos-found-in-uk-homes/

7 https://healthbusinessuk.net/features/how-should-asbestos-%e2%80%a8be-managed-hospitals

7 http://www.asbestosexposureschools.co.uk/pdfnewslinks/LAs%20schools%20containing%20asbestos.pdf

8 https://www.mesothelioma.uk.com/wp-content/uploads/2019/07/British-Asbestos-Newsletter-109_spring_summer_2019.pdf

The Rugby World Cup has been taking the world by storm over the last few months, and with the final drawing ever closer, anticipation is beginning to mount over which team will take home the coveted trophy. Lasting from Friday 20 September to Saturday 2 November, 20 qualifying teams have taken part in the 48-match tournament, including England, New Zealand, Japan, Canada, Australia and Russia.

While each of these nations are undoubtedly skilled in the rugby arena, their take on asbestos legislation, guidelines and procedures varies considerably. We take a look at each of these countries in closer detail, examining their legislative approaches to asbestos usage, production and control measures.

New Zealand

New Zealand have come under scrutiny in recent years regarding their staggered approach to asbestos prohibition, having only banned the trading of asbestos-containing materials (ACMs) three years ago. Asbestos regulations first began back in 1978, with the legislative ban of raw asbestos taking place six years later. However, it wasn’t until 1987 that New Zealand implemented a ban on the production of building materials containing the fibrous mineral, while the prohibition of the import and export of ACMs did not come into place until 2016 under the Management and Removal of Asbestos Regulations (part of the Health and Safety at Work Act 2015).

During the 1970s and 1980s, asbestos use per capita in New Zealand actually exceeded that of the UK and the USA, although this still remained at a considerably lower rate compared to Australia and Canada. In light of this and the country’s lax approach to asbestos prohibition, the mortality rates of New Zealand natives with asbestos-related diseases such as Mesothelioma remain alarmingly high, with 170 people a year losing their lives as a direct result of asbestos exposure.[1]

Despite a national ban now being in place, there are still some loopholes that permit the use of specific ACMs, such as brake linings, gaskets and seals. These materials are only to be imported and used on the basis that there is no other alternative product available, if said alternative would be disproportionately expensive or for research and development purposes.

Australia

Importing a total of 1.5m metric tonnes between 1930 and 1983, Australia once had some of the highest rates of asbestos use per person globally, and, as a result, has the second highest mortality rate for Mesothelioma, with a further 18,000 cases estimated by 2020.[2] Crocidolite was banned in 1967 and amosite use was prohibited in the mid-1980s, but the ban on chrysotile did not come about until 20 years later on 31 December 2003. It was on this day that a full legislative ban was put in place, prohibiting the importation, exportation, usage and production of all forms of asbestos.

Australia’s Work Health and Safety Regulations 2011 comprise a series of guidelines surrounding the management of asbestos in the workplace, including the handling and removal of naturally occurring asbestos, as well as training and licensing requirements. The country has also sanctioned the International Labour Organisation Asbestos Convention, which means that anyone wishing to carry out DIY work is prohibited from removing asbestos from buildings and structures in which it is liable to become airborne, limiting removal works to properly qualified and licensed professionals. This is not the case in New Zealand, where it is still legal for asbestos to be removed by any individual.

Australia was also once home to a series of thriving asbestos mining communities, including the Western Australian town of Wittenoom, which is widely regarded as the most contaminated site in the southern hemisphere. Originally built to aid the mining of crocidolite and as one of the only suppliers of the mineral, Wittenoom was once home to 20,000 residents, more than 10% of which are now suspected to have died from asbestos-related diseases.[3] The mine was officially shut down in 1966 and the last remaining residents are currently being evicted, with the town having been removed from all official maps and road signs. However, asbestos fibres are very much still present and airborne across the area, with the government continuing to encourage residents and tourists to avoid the town.

England

The UK has the highest mortality rate from asbestos-related diseases in the world, a direct result of the British government gradually prohibiting its import, usage and production over a prolonged period of time. Despite voluntary laws banning the import of crocidolite in 1970 and amosite in 1980, legislature prohibiting the trade and usage of these forms of asbestos did not come about until the mid-1980s. The Asbestos Prohibition Regulations 1985 officially prohibited the trade and use of crocidolite and amosite, as well as the production of new ACMs, but chrysotile continued to be imported, produced and used until the nationwide ban in 1999.

There is also a set of legislature known as the Control of Asbestos Regulations set up by the UK government’s Health and Safety Executive (HSE) in 2002, providing guidelines to help duty holders to identify, manage and monitor asbestos on non-domestic premises. These Regulations were updated again in 2006 and 2012, setting a control limit (0.1 asbestos fibres per cubic centimetre of air averaged over a continuous period of four hours), a short-term exposure limit (0.6 fibres per cubic centimetre in the air measured over a 10-minute period), and promoting the use of written records and medical surveillance for workers who come into close, frequent contact with asbestos.

With the ultimate aim of limiting the usage and subsequent disturbance of ACMs in the workplace, the Regulations require all duty holders of non-domestic premises to carry out an asbestos survey and have a management plan in place to determine the location, condition, type and level of risk posed. These guidelines also highlight that any ACMs that are unlikely to be disturbed and are in good condition should be left untouched, which means that there is technically no legislation in place regarding the safe removal of all asbestos from buildings. In light of this, there are still an estimated 14m private domestic properties across the UK which contain asbestos, having been built when the mineral was still being used as a major and legal construction material. What’s more, private domestic properties are exempt from the Control of Asbestos Regulations, placing millions of UK homeowners at continual risk of exposure and asbestos-related diseases.[4]

Canada

Having remained a major exporter of asbestos and ACMs until 2011, Canada is the latest country to have implemented legislation prohibiting the trading, sale, manufacture and usage of the mineral. The Prohibition of Asbestos and Products Containing Asbestos Regulations came into force on 30 December 2018, yet this law contains a number of exemptions which have been met with considerable protest across the country.

Two major industries where asbestos importation, sales and usage is still permitted is across the military and nuclear sectors. The use of military equipment containing asbestos which has been serviced outside of Canada is deemed legal if no feasible alternative is available, and usage of ACMs within nuclear facilities is permitted until 2023. There is also a loophole that allows asbestos to be used in unforeseen circumstances where ACMs are required to protect human health or the environment where there is no viable alternative, as well as a clause permitting the use of the mineral in museum displays and laboratories.

Asbestos is also integral to the chlor-alkali industry – an industrial process for the electrolysis of sodium chloride solutions – with the fibrous mineral acting as a filter in the manufacture of chlorine and caustic soda. Complete prohibition of the substance has been predicted to result in production losses of an estimated $8m per year, so the Canadian government have permitted its usage for a further 10 years.[5] This will allow the nation an extensive timeframe in which to shift production outside of Canada and begin using a more viable alternative in order to comply with the new Regulations.

Despite the closure of Canada’s asbestos mines – with the Jeffery mine in Quebec serving as the world’s largest – certain procedures incorporating the use of asbestos continue to be permitted. Current legislation permits magnesium extraction in asbestos mining residue – of which there are 800 million tonnes still remaining in Quebec – as well as the reuse of road asphalt containing the mineral to restore asbestos mining sites and infrastructure.[6] Therefore, while Canada appears to have completely prohibited asbestos usage and trading on the surface, there are still plenty of areas that need to be addressed in order to make the legislation more watertight.

Japan

In 2005, Japan found itself at the heart of an asbestos scandal following the high number of factory workers and members of the surrounding community that were revealed to have had died from asbestos-related diseases at a former machinery plant in Amagasaki City. This news became all the more alarming when considering the series of legislature that had already been put in place to protect against asbestos exposure. Beginning with the Ordinance on the Prevention of Hazards due to Specified Chemical Substances 1972, this legislation was amended three years later to introduce stricter measures to prevent against asbestos-related diseases. Other regulations included the Air Pollution Control Act 1989, Industrial Safety and Health Law 1995 and Waste Disposal and Public Cleaning Act 1996, all of which help to protect both the public and the environment from the detrimental risks associated with asbestos.

The import, export, usage and manufacture of amosite and crocidolite were first banned in 1995, but chrysotile didn’t become prohibited until 2006. There were certain exemptions to this rule, such as the use of asbestos in gaskets, insulating plates and chemical seals when no feasible alternative was available. These were gradually banned over the following eight years, with the complete prohibition of all remaining ACMs coming into force in 2012. However, it should be noted that asbestos-related deaths are still not expected to peak until 2027, with 103,000 deaths predicted from Mesothelioma alone between 2000 and 2039.[7] This is a direct consequence of Japan serving as one of the world’s largest producers and consumers of asbestos and ACMs throughout the late 20th century, with over 350,000 metric tonnes produced in 1974 alone.

Russia

While 66 countries have completely prohibited asbestos usage, production and trading in all forms, Russia continues to refuse to follow suit. As the world’s largest producer of the fibrous mineral, having manufactured 690,000 metric tonnes of asbestos in 2018, the country shows no signs of slowing down, with mining, production, usage and trading still growing at an increasing pace. To put this into perspective, Russia is responsible for 30% of the world’s asbestos production, exporting 60% of this overall volume to a total of 35 countries.[8]

To this day, a large proportion of Russians continue to use asbestos in their everyday lives, making use of the mineral for insulation, transport and building work. The town of Asbest, located in the heart of the Ural Mountains, is directly named after the mineral and is home to the area where asbestos was first mined in the 1880s, forming one of 41 active asbestos mines and processing facilities across Russia. The town’s 700,000 residents heavily rely on the mining and asbestos industries to make a living, and are continuing to push for the production of the mineral despite awareness of its underlying health risks.

In 2011, a revolutionary law was passed by the Russian government that promised to enforce a series of protective measures to significantly reduce asbestos exposure. While this appeared to be a step in the right direction in terms of the country acknowledging the risks associated with asbestos, this was never properly enforced, and legislation surrounding the prohibition of the mineral still remains an unachievable goal for the foreseeable future.

References

1 https://www.stuff.co.nz/business/110672592/toxic-homes-new-zealands-asbestos-legacy

2 https://www.asbestossafety.gov.au/about-asbestos/about-asbestos

3 https://www.theguardian.com/australia-news/2019/mar/21/final-wittenoom-residents-to-be-forced-out-of-asbestos-ridden-mining-town

4 https://www.dedicatedaccidentsolicitors.co.uk/blog/where-is-asbestos-found-in-uk-homes/

5 http://gazette.gc.ca/rp-pr/p1/2018/2018-01-06/html/reg3-eng.html

6 https://www.asbestos.com/news/2018/10/22/canada-asbestos-ban-exemptions/

7 https://ibasecretariat.org/prof_japan.php

https://www.mesothelioma.uk.com/wp-content/uploads/2019/07/British-Asbestos-Newsletter-109_spring_summer_2019.pdf

8 https://www.statista.com/statistics/264923/world-mine-production-of-asbestos/

As we continue to find ourselves in unprecedented circumstances, SOCOTEC remains committed to ensuring that clients’ facilities are safe, compliant and operational in the wake of the Coronavirus pandemic. As part of its comprehensive offering, SOCOTEC has developed its ‘Business Ready’ recovery programme, offering a series of support packages to cut through the noise and provide organisations with the peace of mind that their staff can safely return to the workplace.

Through its ‘Business Ready’ programme, SOCOTEC can help organisations prepare to restart operations, define their business resumption plan, update their business continuity plans and lead their crisis management strategy. Offering varying levels of support and expertise, from virtual risk assessment training to a full certification service, the packages comprise:

Secure/Secure Plus

Assurance/Assurance Plus

Certification

If you find that the contents of these packages do not match your individual business needs, they can be tailored to match your bespoke requirements. Simply get in touch to discuss your options.

Business Ready – how can SOCOTEC’s Asbestos Management team help?

As part of SOCOTEC’s wider testing, inspection and compliance offering under ‘Business Ready’, our Asbestos Management team can provide a range of services that can help your organisation ensure compliance across three key areas during the COVID-19 pandemic.

Statutory Compliance

There is a reasonable chance that your scheduled asbestos inspection or reinspection was due during the COVID-19 lockdown and had to be delayed as a result. With workplace restrictions beginning to ease, it is prudent for these inspections to be planned and completed to ensure that materials are in a safe and compliant condition. SOCOTEC can assist with your asbestos inspection and reinspection requirements as you begin the reoccupation process.

Projects

Essential refurbishment work for your building may also have been delayed as a result of the pandemic. Intrusive surveys should be undertaken prior to any planned building works, which may include any adaptations to provide additional barriers/segregation for COVID-19 mitigation measures, as well as general refurbishment works. SOCOTEC is able to carry out intrusive asbestos refurbishment surveys in line with UKAS No. 0148 regulations, ensuring compliance with an organisation’s ‘Duty to Manage’.

If many of your staff continue to work from home and you are not planning on fully reoccupying your building for the foreseeable future, you may wish to consider intrusive inspections that could influence future projects while the building is at low occupancy.

Policy

With staff numbers likely to be reduced through the government employment retention scheme, it is worth considering whether or not your organisation’s asbestos management plan requires reviewing and amending in relation to the roles and responsibilities of the assigned parties.

Additional services

Given that the Control of Asbestos Regulations (CAR) 2012 require dutyholders to manage asbestos to prevent or minimise exposure as far as is reasonably practicable, it is essential that both the short and long-term management of asbestos is not overlooked during the ongoing crisis.

As a leading provider of asbestos management and consultancy services across a wide range of business sectors and property types, SOCOTEC has been able to offer a full suite of asbestos consultancy services throughout the current crisis. This is driven by one of the largest compliments of technical staff in the market, as well as our own in-house UKAS accredited testing laboratories. Services that our Asbestos Management team can deliver include:

UKAS accredited management/refurbishment/demolition asbestos surveys

Asbestos sampling and material identification

Asbestos in soil analysis and full quantification

Asbestos air monitoring and 4-stage clearance

Project management of asbestos removal works

UKATA and CIBSE approved asbestos awareness training

Enforcement liaison.

Where site visits are required, please note that SOCOTEC staff continue to adhere to social distancing guidelines and safety measures issued by the government at all times. For more information on SOCOTEC’s full range of asbestos services.

Virtual health and safety training – Asbestos Awareness

While SOCOTEC is temporarily unable to deliver UKATA’s Asbestos Awareness training face-to-face in light of current social distancing guidelines, our Health & Safety Consultancy team is able to provide an extended e-learning module which features exactly the same content as that in the original course, with certification valid for 12 months.

With the official roadmap out of the third UK lockdown now in place, businesses are starting to look ahead as to how they can return their workplaces to their former operational capacity. SOCOTEC is committed to ensuring that clients’ facilities are safe, compliant and fully functional in the wake of the Coronavirus pandemic, having developed its ‘Business Ready’ recovery programme to cut through the noise and provide organisations with a series of support packages and the peace of mind that their staff can safely return to the workplace.

SOCOTEC’s Asbestos Management team offers a range of testing, inspection and compliance services that can help your organisation ensure compliance while getting your facilities back to full capacity. With the ability to address any shortfallings in compliance that may have arisen in the wake of the pandemic while facilities have been under-occupied, SOCOTEC can assist across three key areas:

Statutory Compliance

There is a reasonable chance that your scheduled asbestos inspection or reinspection was due over the course of the COVID-19 pandemic and has had to be delayed as a result. With lockdown restrictions gradually beginning to ease, it is prudent for these inspections to be planned and completed to ensure that materials are in a safe and compliant condition. SOCOTEC is well equipped to assist with your asbestos inspection and reinspection requirements as you begin the reoccupation process.

Projects

Essential refurbishment work for your building may also have been delayed as a result of the pandemic. Intrusive surveys should be undertaken prior to any planned building works, which may include general refurbishment works or any major projects that you have planned. SOCOTEC is able to carry out intrusive asbestos refurbishment surveys (UKAS No. 0148), ensuring compliance with Control of Asbestos Regulations (CAR) 2012.

If many of your staff are currently working from home and you are not planning on fully reoccupying your building to full capacity at the moment, you may wish to consider intrusive inspections that could influence future projects while the building remains at low occupancy.

Policy

With staff numbers likely to have altered over the past year, as well as possible changes to named personnel having taken place, it is worth considering whether or not your asbestos management plan requires reviewing and amending in relation to the roles and responsibilities of the assigned parties.

Additional services

Given that CAR 2012 requires dutyholders to manage asbestos to prevent or minimise exposure as far as is reasonably practicable, it is essential that both the short and long-term management of asbestos is not overlooked during the ongoing crisis.

As a leading provider of asbestos management and consultancy services across a wide range of business sectors and property types, SOCOTEC has been able to offer a full suite of asbestos consultancy services throughout the current crisis. This is driven by one of the largest compliments of technical staff in the market, as well as our own in-house UKAS accredited testing laboratories. Services that our Asbestos Management team can deliver include:

• UKAS accredited management/refurbishment/demolition asbestos surveys

• Asbestos sampling and material identification

• Asbestos in soil analysis and full quantification

• Asbestos air monitoring and 4-stage clearance

• Project management of asbestos removal works

• UKATA and CIBSE approved asbestos awareness training

• Enforcement liaison.

Where site visits are required, please note that SOCOTEC staff continue to adhere to social distancing guidelines and safety measures issued by the government at all times.

Asbestos Awareness training

While the average number of delegates undertaking or refreshing their UKATA Asbestos Awareness training is currently at a five-year low, it is absolutely crucial that up-to-date knowledge of health and safety guidance and legislation is maintained (as per Regulation 10 of CAR 2012). SOCOTEC’s Asbestos team can deliver face-to-face UKATA Asbestos Awareness training and refresher courses in line with social distancing guidelines, as well as offering virtual classrooms via Microsoft Teams that can be tailored to your business’ individual requirements.

An asbestos management plan is a document outlining how asbestos will be managed within a property. It details the activities required to protect occupants against exposure to asbestos fibres.

It's recommended to update your asbestos management plan every 12 months. If relevant guidance or legislation has been updated or there has been an asbestos related incident, the current asbestos management plan might not be suitable and should be updated.

A compliance or gap analysis audit can help to identify whether elements of a duty holder’s asbestos management is effective and fully compliant with CAR (2012) and other relevant legislation or guidance.

Are you Business Ready?

COVID Secure

Learn more about how SOCOTEC can help ensure compliance during COVID-19.

Learn more about how SOCOTEC can help ensure compliance during COVID-19.

Asbestos Management

From management plans to air monitoring, SOCOTEC is well equipped to help your organisation become fully compliant with specific legislature and health and safety regulations surrounding asbestos.