As a leading technical expert with extensive experience in carrying out intrusive and non-intrusive structural investigations, SOCOTEC can provide RAAC advice to customers concerned about the presence of Reinforced Autoclaved Aerated Concrete in their building(s).

What is RAAC?

RAAC stands for Reinforced Autoclaved Aerated Concrete. It has a “bubbly” appearance but differs from traditional concrete in that there are no coarse aggregate stones in the mix. The material is much lighter and softer than normal dense concrete. Hence the term concrete is somewhat of a misnomer and the material is better described as an aerated silicate product.

It was invented in the 1930s in Sweden and introduced to the UK in the 1950s. The product was thought to be in use until the mid-1990s. In the main the material was used to manufacture planks commonly used in roof structures, although less commonly they can be found in walls and floors.

The planks generally are 600mm wide and span 6m forming a groove in between neighbouring planks.

Safety Concerns

Safety concerns have been raised concerning these structures which are now well passed the service life of thirty years. These include the very real possibility of sudden failure due to design deficiencies such as insufficient reinforcement anchorage and poor bearing length.

How can we help?

With the agility, flexibility, and a nationwide network of experts, SOCOTEC is ideally positioned to provide clients with the reassurance of a single source of support for all RAAC related concerns and needs. Our experienced team can provide a range of services including desktop studies, structural surveys and investigations, non-intrusive and intrusive testing, risk assessments, remedial advice, design and management support. Further to this, we can also support with asbestos surveys, fire risk assessments and CDM that may also be necessary during the works.

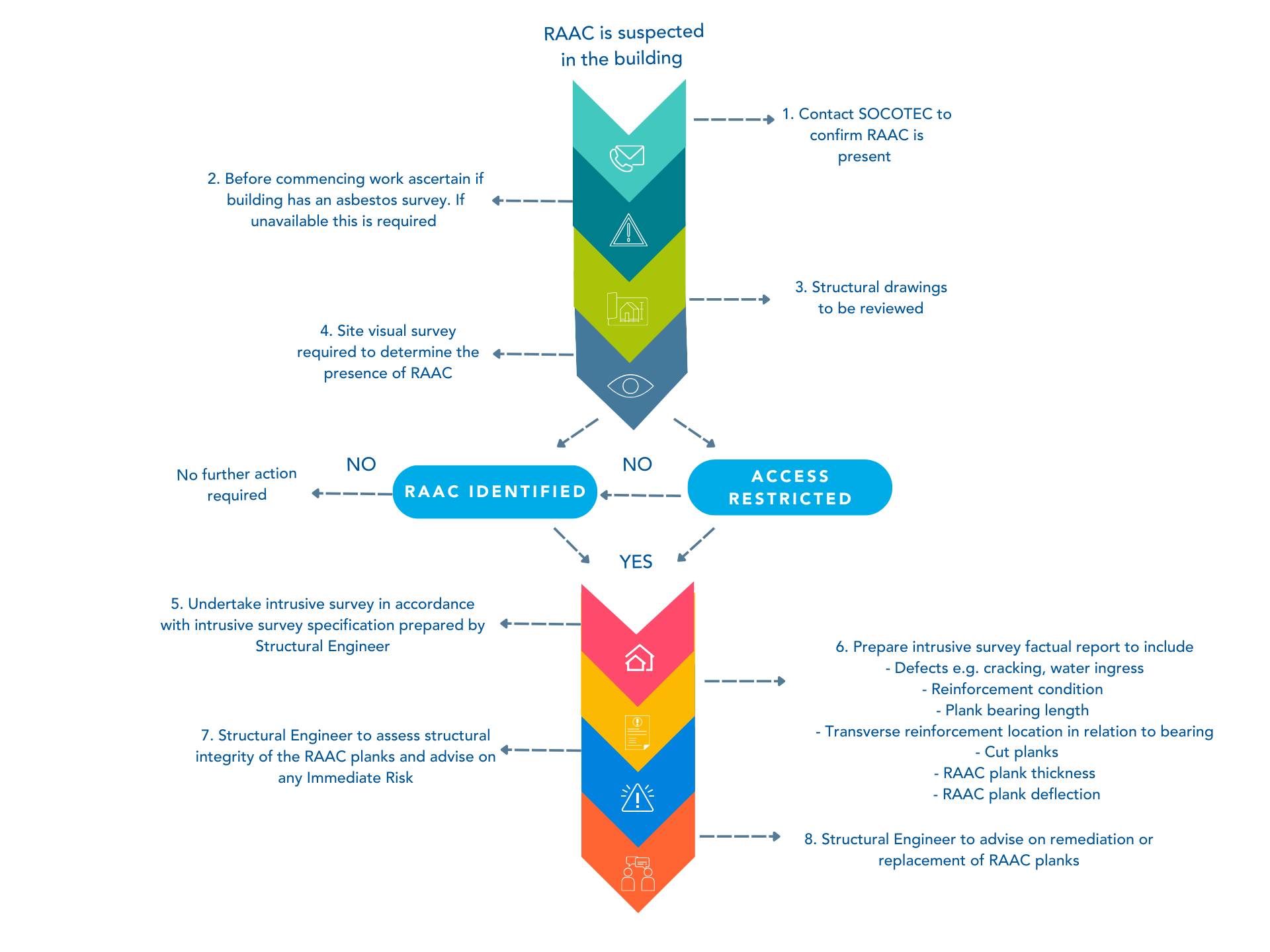

We understand that a swift and straightforward approach is paramount, and we aim to ensure that our process is as simple as possible, as summarised below:

Talk to our experts

Structural Investigations

› A desk study of all available maintenance and design information

› An on-site technical inspection and survey of the building structure to identify whether RAAC is present, the condition and the level of risk, non-intrusive and intrusive testing. The survey will include:

- Measurement of deflections

- Recording of cracks and defects

- Recording evidence of water leaks

- Hammer tap testing for signs of debonding concrete

- Recordings of panels cut after manufacture.

- Recording of any alteration or penetration through panels after construction

› Risk assessment and engineering assessment

› Recommendations and management options for remedial action to either strengthen or replace the RAAC planks.

Asbestos and RAAC

Asbestos Risk

Both asbestos and RAAC were used during the same time periods, meaning there is often a dual threat that must be considered when undertaking investigation and remedial design, for RAAC risk. Often areas requiring inspection for RAAC will be concealed and require intrusive investigation. All buildings should have an asbestos register, but this is often not suitable for intrusive works and an intrusive asbestos survey (an Asbestos Refurbishment Survey) will be required to ensure potentially hidden asbestos materials are not disturbed.

In a similar vein, where asbestos materials are found to be present the services of an Asbestos Removal Contractor may be required to facilitate access beyond asbestos materials, or to undertake removal works as part of a remedial programme.

Our in house experts can offer UKAS accredited asbestos surveys in line with HSG 264, UKAS accredited asbestos air monitoring in line with HSG 248 and asbestos project management and specification of remedial/removal works. These services can often be deployed alongside our RAAC site investigation services, to streamline the process and provide much needed data in a timely manner.

Both asbestos and RAAC were used during the same time periods, meaning there is often a dual threat that must be considered when undertaking investigation and remedial design, for RAAC risk. Often areas requiring inspection for RAAC will be concealed and require intrusive investigation. All buildings should have an asbestos register, but this is often not suitable for intrusive works and an intrusive asbestos survey (an Asbestos Refurbishment Survey) will be required to ensure potentially hidden asbestos materials are not disturbed.

In a similar vein, where asbestos materials are found to be present the services of an Asbestos Removal Contractor may be required to facilitate access beyond asbestos materials, or to undertake removal works as part of a remedial programme.

Our in house experts can offer UKAS accredited asbestos surveys in line with HSG 264, UKAS accredited asbestos air monitoring in line with HSG 248 and asbestos project management and specification of remedial/removal works. These services can often be deployed alongside our RAAC site investigation services, to streamline the process and provide much needed data in a timely manner.

Fire Safety

Fire Risk Assessments

Where the presence of RAAC is confirmed, a review of an existing fire risk assessment should be considered by the Responsible Person. The location of the RAAC, any subsequent construction works and its relation to fire strategy for the building will also require careful consideration as it has the potential to impact the fire safety of the building and its use.

Where mitigation measures are in place due to the presence of RAAC, careful consideration should also be given to changes in building capacity and evacuation strategies.

Our experienced team of Fire Engineers and Fire Safety Consultants can offer solutions to ensure compliance with relevant fire safety legislation by driving down risk. We work with some of the UK’s largest portfolios offering services such as fire strategies, fire risk assessments, compartmentation surveys, fire door surveys, training, and ad hoc advice.

Where the presence of RAAC is confirmed, a review of an existing fire risk assessment should be considered by the Responsible Person. The location of the RAAC, any subsequent construction works and its relation to fire strategy for the building will also require careful consideration as it has the potential to impact the fire safety of the building and its use.

Where mitigation measures are in place due to the presence of RAAC, careful consideration should also be given to changes in building capacity and evacuation strategies.

Our experienced team of Fire Engineers and Fire Safety Consultants can offer solutions to ensure compliance with relevant fire safety legislation by driving down risk. We work with some of the UK’s largest portfolios offering services such as fire strategies, fire risk assessments, compartmentation surveys, fire door surveys, training, and ad hoc advice.

Health and Safety

Ensuring Safety when dealing with RAAC

A high percentage of site-based activity regarding RAAC remediation will involve working at height and the use of access equipment such as ladders, MEWPS or even roof access systems. Keeping workers safe while working at heights is critical, especially when it comes to working on roofs. Falling from heights is still the top cause of fatality in the workplace. Roof safety is not just a priority, it’s a necessity, so it is crucial that Health & Safety and risk management is considered throughout the process, including the assessment of contractor’s competency for any planned works and the review of site and task specific risk assessments & method statements (RAMS) to help ensure the safety of all and compliance with regulations.

For large programmes of remediation works, it is equally important to ensure that risks are kept to a minimum and where unavoidable, safe systems of work are in place to reduce the level of perceived risk so far is reasonably practicable. Regular Health & Safety Site Inspections should be undertaken to help identify any deficiencies or deviations from approved safe systems of work and can help to ensure that high standards of safety and continual improvements in the management of health and safety on site.

Where RAAC is removed, this could involve the complete vacation of the building and there could be the need to use temporary accommodation to allow the continued use of the same site. Suitability and set up of these buildings is important to ensure compliance with site and welfare regulations, and will require careful planning to ensure risks are minimised. In addition, traffic management plans will often be required, and additional fire risk assessments undertaken to reflect the changes to the site.

We have a nationwide Health & Safety Consultancy who work extensively in the construction sector and specialise in working in height, risk management, CDM and asbestos and are well placed to assist any support requirements you may have.

A high percentage of site-based activity regarding RAAC remediation will involve working at height and the use of access equipment such as ladders, MEWPS or even roof access systems. Keeping workers safe while working at heights is critical, especially when it comes to working on roofs. Falling from heights is still the top cause of fatality in the workplace. Roof safety is not just a priority, it’s a necessity, so it is crucial that Health & Safety and risk management is considered throughout the process, including the assessment of contractor’s competency for any planned works and the review of site and task specific risk assessments & method statements (RAMS) to help ensure the safety of all and compliance with regulations.

For large programmes of remediation works, it is equally important to ensure that risks are kept to a minimum and where unavoidable, safe systems of work are in place to reduce the level of perceived risk so far is reasonably practicable. Regular Health & Safety Site Inspections should be undertaken to help identify any deficiencies or deviations from approved safe systems of work and can help to ensure that high standards of safety and continual improvements in the management of health and safety on site.

Where RAAC is removed, this could involve the complete vacation of the building and there could be the need to use temporary accommodation to allow the continued use of the same site. Suitability and set up of these buildings is important to ensure compliance with site and welfare regulations, and will require careful planning to ensure risks are minimised. In addition, traffic management plans will often be required, and additional fire risk assessments undertaken to reflect the changes to the site.

We have a nationwide Health & Safety Consultancy who work extensively in the construction sector and specialise in working in height, risk management, CDM and asbestos and are well placed to assist any support requirements you may have.

CDM2015 Regulations

All RAAC remediation projects will need to comply with The Construction (Design and Management) Regulations 2015, and in most cases will require the client to appoint various duty holders, including the Principal Contractor and Principal Designer. The Principal Designers role during construction works is to plan, manage and monitor the pre-construction phase and coordinate matters in relation to health and safety.

This role is vitally important to not only ensuring compliance with the CDM2015 Regulations, but coordination of health and safety at the early design phase of remediation programmes.

We have an in-house nationwide team of experienced consultants who have years of experience in supporting clients across a wide range of standard and complex construction projects and who can help assist clients and contractors to comply with their duties under the CDM Regulations.

If you would like to know more about how we can provide support, please email raac@socotec.co.uk

Need expert advice on RAAC?

Check out our latest News & Media

Ecology – A Green Trust Service

Decoding Transformer Performance with Oil Testing

Heritage Consultancy - Why it Matters

Inside PFAS: Sampling, Science & The Future

SOCOTEC UK & Ireland makes multi-million pound apprenticeship investment

Discover the Future of Highway Surveys: Traffic Speed Video & GPR Insights

SOCOTEC represented at Downing Street for Employment Rights Act launch

Sustainability - Building compliance Explained