Need some advice?

Leave your details and we will get in touch.

I want to be contacted by an expert1 /

Ensuring the safety and security of employees and passengers is a key priority for every rail organisation, and lighting has a crucial role to play in this. Adequate lighting allows employees to assess any potential risks to themselves and the general public, as the quicker it is to spot a hazard, the easier it is to avoid. What’s more, poor lighting caused by lux levels set at too low or high a level forces eyes to work harder, leading to eyestrain and Sick Building Syndrome, with symptoms ranging from irritation, itchiness, blurred/double vision to headaches and fatigue.

From track and tunnel maintenance to operating rolling stock, the varying working conditions presented by the rail industry means that the lighting and control measures required for safe working conditions can vastly differ. It can often prove difficult to identify whether the lighting in use is at an adequate level to ensure it is safe and compliant, with regular monitoring recommended to determine the safety and wellbeing of employees and passengers at all times.

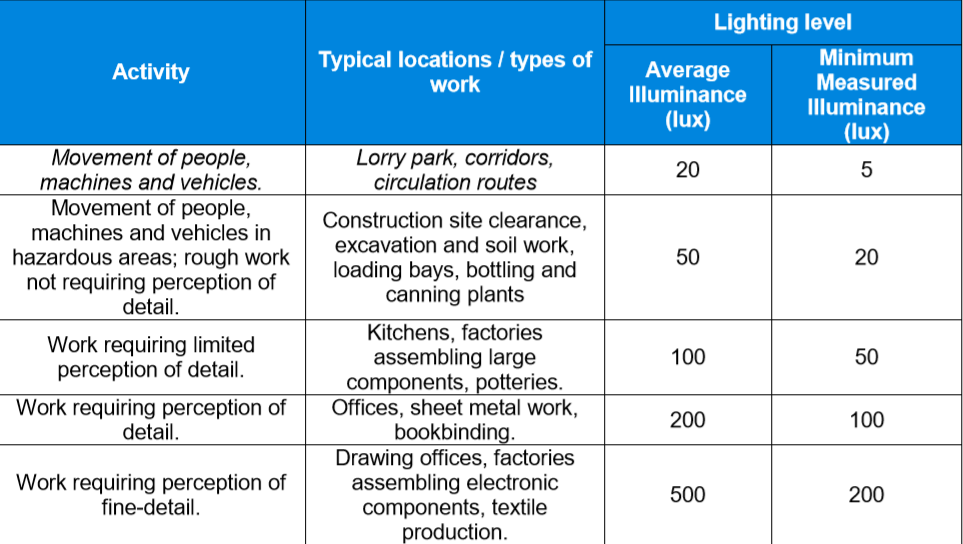

HSG 38 Lighting at Work 1997 provides detailed information about the management of light hazards and the possible solutions that could be implemented. The amount of light on a surface affects the employee’s vision, with higher illuminance required the finer the detail of work being carried out. Guidance for effective illuminance (lux) levels and assessment of lighting conditions within various workplaces is given in HSG38, with recommendations for average and minimum measured lux levels for different work activities and environments indicated below:

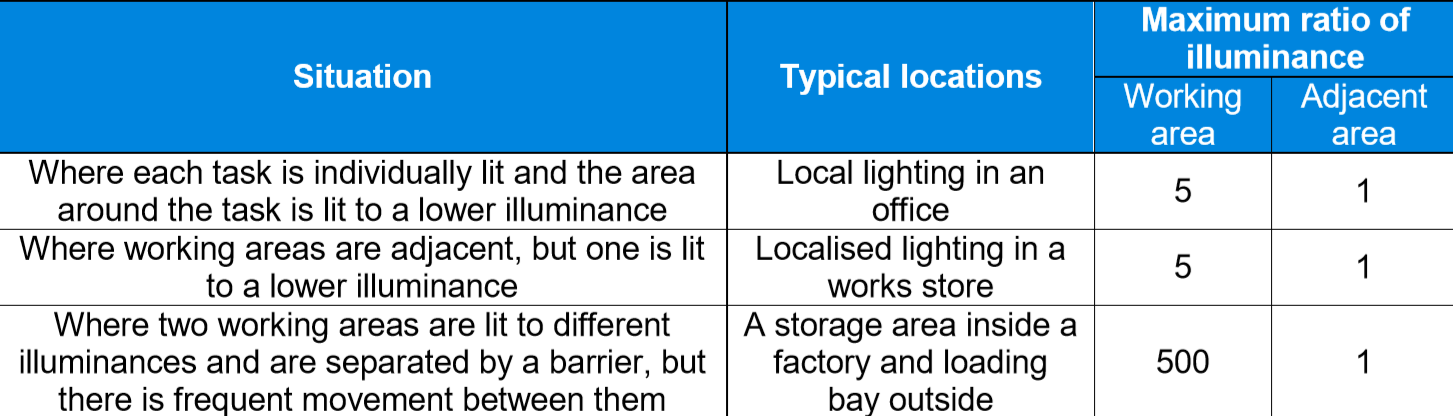

Maximum ratios of illuminance for adjacent areas are also included within HSG 38 Lighting at Work 1997, as large differences in illuminance may cause visual discomfort and affect safety in areas where there are frequent pedestrians. These levels are indicated in the table below:

Regulation 8 of the Workplace (Health, Safety and Welfare) Regulations 1992 requires every workplace to have suitable and sufficient lighting, which should be natural as far as is reasonably practicable. Several aspects of lighting in the workplace must be considered within this legislation, including lighting design, the type of work being undertaken, the work environment, health aspects, individual requirements, lighting maintenance, replacement, disposal and emergency lighting.

Finally, BS EN 12464 supplies information regarding the luminous environment in the workplace, with a particular emphasis on the lighting requirements needed to undertake specific tasks. There is also legislation surrounding emergency lighting – namely, BS EN 1838 and BS 5266-1.

Employers and those responsible for the management of non-domestic premises have a legal duty to ensure the health and safety of their employees, and this includes ensuring that lighting is safe and does not pose a safety risk to employees and those who may use these premises. There are a number of factors that employers must take into account when implementing and maintaining lighting in the workplace, such as:

There are several lighting hazards that rail organisations may come across which can affect employee and passenger health and safety. These include:

The type of lighting installation required to ensure adequate working conditions depends on a number of factors, including suitability, the size of area where the work is being carried out, the physical constraints of the space and the purpose for which it will be used. The amount of light on a surface affects our ability to see, with a higher amount of illuminance required if the work being carried out requires a significant amount of detail. For this reason, interior and exterior lighting needs to achieve a reasonable illuminance across all relevant working areas, with uniform illuminance required to ensure that all tasks can be carried out to the best of an employee’s ability.

Monitoring and reviewing lighting conditions is essential to guaranteeing employee and passenger safety, ensuring that the required standards have been met and altering these where necessary to ensure the highest standards of health and safety. SOCOTEC recently carried out an external lighting survey at a depot on behalf of a major rolling stock manufacturer to identify whether existing light levels on footpaths in between train roads are within comfort levels (as indicated in HSG 38).

To carry out the monitoring service, a light meter sensor was mounted on a tripod and all measurements were taken at one metre high. Monitoring was conducted on an ‘as-is’ basis, which involved taking lux measurements across various areas of the site, noting areas of particularly poor lighting and advising recommended actions where required. Average, minimum and maximum levels were calculated from the measurements taken of the lighting itself, and from the data obtained, it was determined that the average lighting levels were just below the acceptable for circulation footpaths, with lighting improvements required in some areas, as well as the need for illuminance uniformity to be increased.

Lighting levels were variable in most areas, largely due to the presence of a number of failed and non-working lights. As a result, SOCOTEC recommended that the client implement a lighting maintenance programme to repair lights as and when required, with additional calls for improvement on illuminance levels.

SOCOTEC’s Occupational Hygiene team can carry out lighting surveys to provide your organisation with the peace of mind that the lighting is fully compliant with the relevant health and safety legislation and guidance. Examples of support that SOCOTEC can provide in this area includes workplace exposure monitoring, Sick Building Syndrome investigation and workplace comfort assessments.

For further information about how SOCOTEC can support your organisation with its lighting requirements, click here or get in touch.