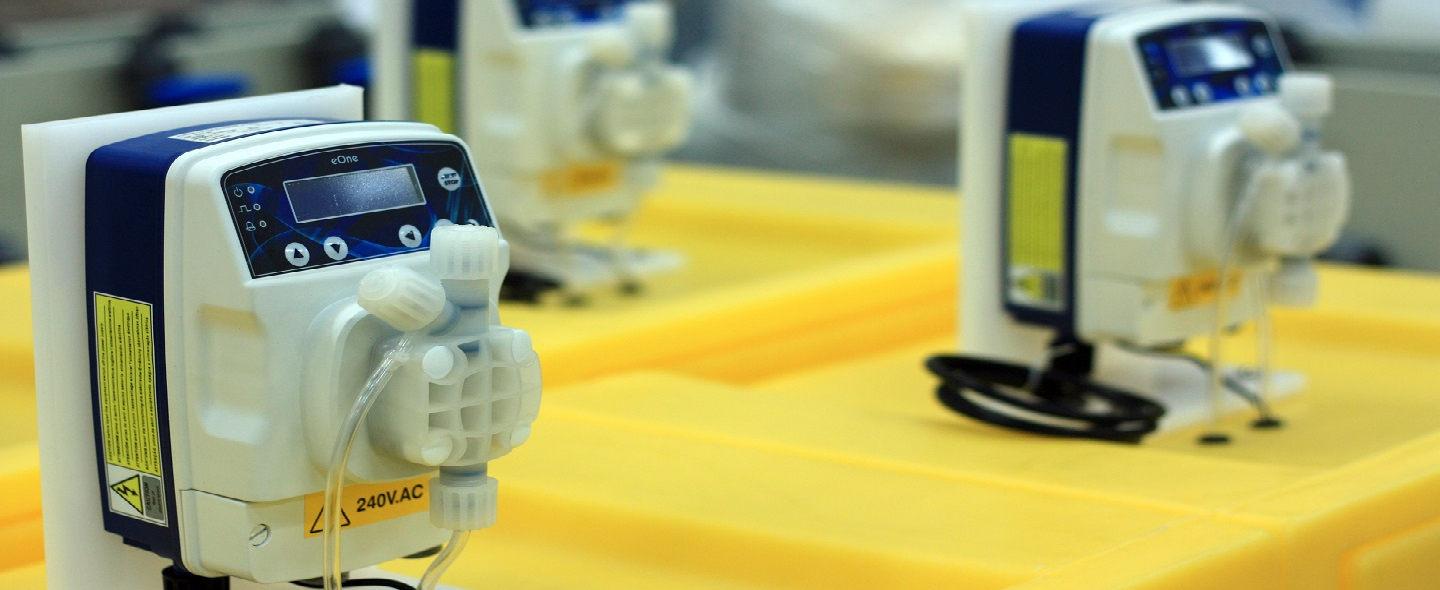

Using dosing and control equipment ensures your water systems are fed the right amount of chemicals to treat the systems.

SOCOTEC offers a range of dosing and control equipment, depending on the requirements of your water system; cooling tower dosing and closed circuit dosing are two common systems that benefit from the treatment.

Closed Circuit Dosing

- Inhibitor and biocide dosage - set to the required dosage ratio, with the inhibitor set to be proportionally dosed to the make up. Using a digital control timer, dosing pumps run for the desired duration and can be readily adjusted to suit parameters and routine monitoring of inhibitor levels

- Stainless steel chemical dosing pots - required to feed liquid chemicals such as corrosion inhibitors into closed systems, with the stainless steel reducing micro bacteria as well as reducing friction and the energy required to pump the water around the system

- Glycol blending units - fully automated to make-up the supply for glycol treated water systems and maintain the pre-set blend ratio. Glycol is drawn direct from the supply container or chemical storage tank. Blended water solution is supplied at the same pressure as the incoming water supply.

Cooling Tower Dosing

- Bleed-off controls - controls the accumulation or build up of dissolved solids by recirculating water caused by evaporation, using two types of methods: conductivity and proportional bleed-off systems

- Inhibitor dosage - corrosion and scale inhibitors are dosed in proportion to the make-up to maintain a set level in the recirculating water

- Biocide dosage - using two types of methods: non-oxidising (dosed on alternating basis using timer controlled dosing pumps)or oxidising biocides (dosed continuously at low level to maintain disinfectant levels)

- Chemical dosing pumps - either diaphragm pumps (capable of injecting high pressures up to 20 bar) or peristaltic pumps (using system of rollers compressing a tube to create a flow)

- Towerpack units - using higher pressure diaphragm pumps (5 bar injection pressure on standard units with 10 bar option) together with conductivity bleed-off control using electrodeless maintenance free probe

Talk to our experts

Want to find out more about SOCOTEC's Water services? Contact us

Get in touch sam.bremner@socotec.com

You might also be interested in:

No related media yet for that topic, feel free to visit our Media library.